APM-PROC-APO Panel Meter

Digital Panel Meters TRUAPM for 4-20mA, 0-10V input signals

The Trumeter APM-PROC-APO features a highly visual, easy to read, display and a versatile range of analogue inputs, this Process Meter takes APM into a

wide range of new industrial applications.

The user programmable scale and customized annunciators allow users to specificaly tailor the meter to display their critical parameters exactly

to what they want, whilst the dynamic back-lighting, combined with set points, means users are instantly, visually alerted when the

measured input is out of range. The two outputs can be used to integrate into other systems, such as SCADA and BMS.

Innovative design technology brings a greater level of accuracy to the APM range through input signal optimization. An accuracy of 0.1% or better can now be achieved, allowing for more precise measurement, digital display and control.

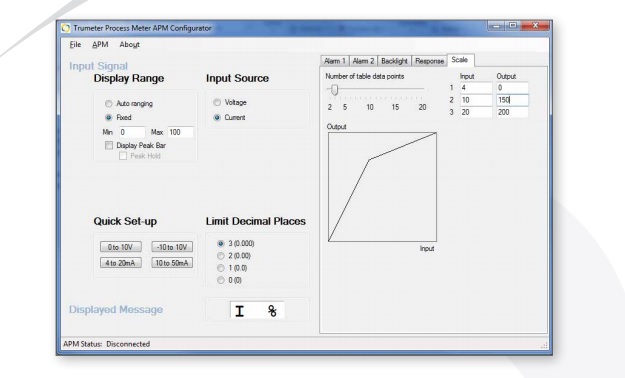

Non linear sensors, from devices such as pressure transducers, can also be used thanks to the new APM Configurator

application that allows the user to configure upto 20 points in a non linear conversion table.

APM-PROC-APO Applications

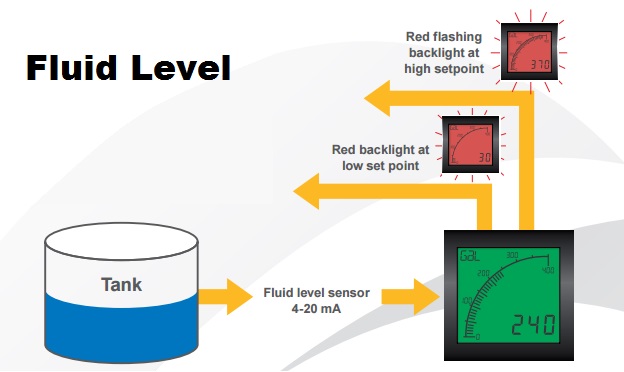

The APM Process digital panel meter is used to display the volume of liquid in the tank. The 4-20mA analog output from the liquid level sensor is scaled to gallons, and the custom annunciator set to "Gal", all via the easy-touse software application. High and low setpoints are configured so that the normal green display will flash red when the tank is too full or empty, alerting the operator. Additionally the APM digital outputs are integrated into the tank pumping system and the tank is automatically drained or filled if the setpoints are exceeded.

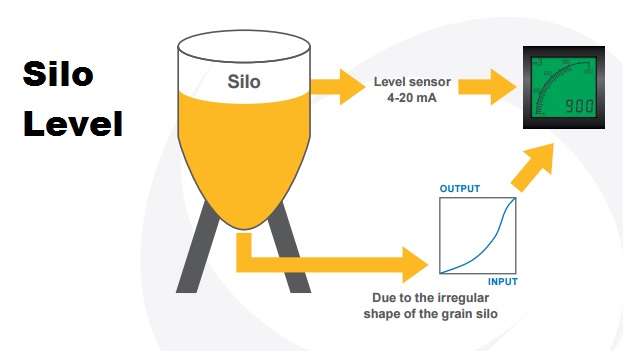

The APM-PROC-APO Process Meter is used to provide digital display of the material volume in the

silo, using the analogue output from a

level sensor.

The signal from the sensor is scaled into

the measurement units cubic metres,

and the annunciator customised to m3

, all

via the easy-to-use software. Due to the

irregular shape of this silo, the 20-point

non linear table is used to correct the

non-linear signal from the sensor.

The displayed value accurately shows

the volume in the silo. High or low

setpoints can be set, and the APM

can be integrated into other systems

for process control.

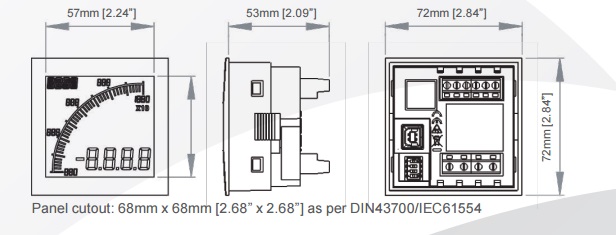

Physical Dimmension TRUAPM

Specification TRUAPM

INPUT VOLTAGE

Range (DC) VOLTAGE 0 to +/- 10VDC CURRENT 0 - 50mA

Impedance VOLTAGE100 Kohms CURRENT 15 ohms

Accuracy VOLTAGE0.1% CURRENT 0.01%

ENVIRONMENTAL

Temperature - operating -10 to +60 degC

Temperature - storage -40 to +70 degC

IP rating (from the front) IP65

POWER SUPPLY

Nominal Input (AC or DC) 12-24 VAC/VDC

DISPLAY

Number of digits 4

Digit height 12mm [0.47"]

Number of message characters 4

Backlight colours Red, Green, White

LCD display Positive or Negative

OUTPUTS

Max voltage 24V

Max current 500mA

Analogue output 4-20mA

CERTIFICATION UL and cUL, CE, RCM Approval

Software for TRUAPM Panel Meter

- HOME

- HMI & PLC

- SIGNAL CONVERTER

- DIGITAL PANEL METERS

- PID TEMPERATURE CONTROLLERS

- TIMERS & COUNTERS

- SENSORS

COPYRIGHT 2010 - 2025 UCONTROL PTY LTD AUSTRALIA ABN 18 150 270 161