PLC & HMI Solutions

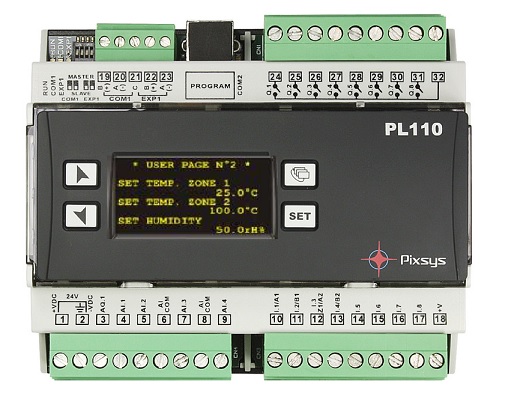

Pixsys PL110 Micro PLC

PL110 PLC with Modbus

Micro PLC high functionality. 16 digital I/O including 2 x NTC sensor, 4-20mA & 0-10V signal. 1 analogue output 0-10V, 2 serial port RS485 & RS232 ModBUS RTU serial communications master and slave. Timers counters bistables markers PID blocks recipe indexing and more. Programming by Free PLProg ladder based software & standard USB printer lead. Optional 16 page 4 line display.

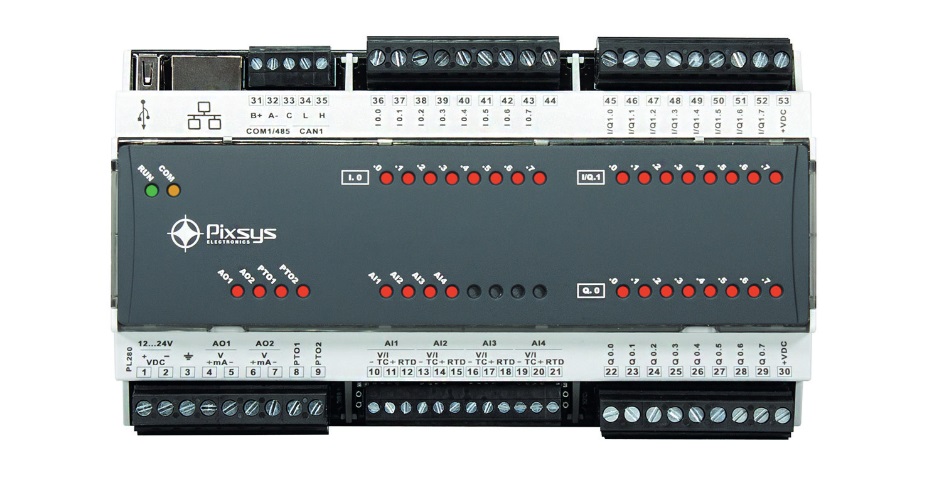

Pixsys PL280 PLC

PL280-1AD Compact PLC with Modbus TCP RTU IEC61131

Compact PLC for applications requiring flexibity with up to 28 digital I/O. All the resources are available in a single device. CPU, power supply unit, digital I/O, 4 x analogue inputs including mA, volts, RTD, thermocouple sensors K,J,R,S not requiring external signal conditioners. 2 x Analogue outputs mA/V. Serial communication via Ethernet Modbus TCP Master/Slave, Can Open, RS485 multi-point and Modbus RTU, counters, timers, PID control algorithms, motion control, mathematical and logical functions, IEC61131 program environment

PL700 Modular PLC

PL700 PLC CPU with Codesys Development Environment

Specification Codesys PL700 PLC CPU

PL700 is the Pixsys PLC CPU integrating Codesys Control SL v.3.5 runtime, programmable by CODESYS development environment. This CPU supports following CODESYS fieldbuses: CANopen Manager (Master), EtherCAT Master, EtherNet/IP Adapter (Slave), Modbus TCP Master / Slave, Modbus Serial Master, PROFINET Device (Slave).

Acquisition of local I/Os is possible via integrated fieldbus PLE-DIN-BUS for the Pixsys modules PLE500 and via RS485/ModbusRTU or CANopen for Pixsys remote I/O Modules MCM260X

Pixsys TD410 4.3" HMI with Modular PLC ability

TD410-AD

Pixsys TD710 7" HMI with Modular PLC Ability (Replaced by TD710-A-2ETH)

TD710-AD

HMI 7" integrating soft-plc + 1 RS485 + 1 CANopen + 1 Ethernet + Movicon CE Lite (TD710-2ETH-A 2 ethernet port with sperate MAC address)

204 x 160 (front panel) x 35

Power supply 12...24 V AC / V DC +/-15% 50/60 Hz (galvanic isolation 2500V)

Processor ARM Cortex A8 @ 1 GHz

Memory eMMC 4 GB/ RAM 512 MB DDR3

Serial communication RS232-RS485 (1200..115200 Baud) galvanically isolated

Sealing Front Panel IP65

Supports 2 x ETD1644 Expansion Module

HMI 7" integrating soft-plc + 1 RS485 + 1 CANopen + 1 Ethernet + Movicon CE Lite (TD710-2ETH-A 2 ethernet port with sperate MAC address)

204 x 160 (front panel) x 35

Power supply 12...24 V AC / V DC +/-15% 50/60 Hz (galvanic isolation 2500V)

Processor ARM Cortex A8 @ 1 GHz

Memory eMMC 4 GB/ RAM 512 MB DDR3

Serial communication RS232-RS485 (1200..115200 Baud) galvanically isolated

Sealing Front Panel IP65

Supports 2 x ETD1644 Expansion Module

Pixsys TD810 & TD820 HMI with Modular PLC Ability

TD810-AD 10.4" TD820-AD 12.1"

HMI 10" integrating soft-plc + 1 RS485 + 1 CANopen + 1 Ethernet + Movicon CE Lite

TD810 274 x 216 x 35 mm

TD820 317 x 256 x 35 mm

Power supply 12...24 V AC / V DC +/-15% 50/60 Hz (galvanic isolation 2500V)

Processor ARM Cortex A8 @ 1 GHz

Memory eMMC 4 GB/ RAM 512 MB DDR3

Serial communication RS232-RS485 (1200..115200 Baud) galvanically isolated

Sealing Front Panel IP65

Supports 2 x ETD1644 Expansion Module

HMI 10" integrating soft-plc + 1 RS485 + 1 CANopen + 1 Ethernet + Movicon CE Lite

TD810 274 x 216 x 35 mm

TD820 317 x 256 x 35 mm

Power supply 12...24 V AC / V DC +/-15% 50/60 Hz (galvanic isolation 2500V)

Processor ARM Cortex A8 @ 1 GHz

Memory eMMC 4 GB/ RAM 512 MB DDR3

Serial communication RS232-RS485 (1200..115200 Baud) galvanically isolated

Sealing Front Panel IP65

Supports 2 x ETD1644 Expansion Module

12.1 Inch HMI with 2 Independant Ethernet Ports and Soft PLC

TD820-2ETH-AD Full Specification

Resistive Touch screen 1280x800, ratio 16:9

Based on the WEC 7 operating system and ARM CORTEX A8 processor, with integrated solid-state memory, the panel is programmable with Movicon 11.6, allowing interface with the most popular PLC brands. Connectivity includes an opto-isolated RS485 serial port and two 10/100 Ethernet ports with distinct MAC address to allow separation between the machine/plant network and the company network (ERP, Industry 4.0, Internet access).TC570-830 Codesys HMI's with 2 Independant Ethernet Ports and Soft PLC

7" to 15.6" Capacitive and resistive Touch HMI with distributed and rear mount expandable I/O

TC570-830 Codesys HMI Specification

Capacitive Touch screens up to 15.6" 1366x768, ratio 16:9

Operator panel which integrates CODESYS v. 3.5 runtime on Linux Yocto operating system. Docker functionality allows parallel activation of other applications. The wide range of fieldbuses supported by Codesys, as well as the OPC UA standard, provides extensive connectivity and application flexibility. Connectivity includes two 10/100 Ethernet ports with separate MACs in order to allow separation between machine/plant network and enterprise network (management, Industry 4.0 , Internet access) in addition to RS485 serial and CANOpen.Programme Software for TD Range HMI/PLC

Pixsys Suite

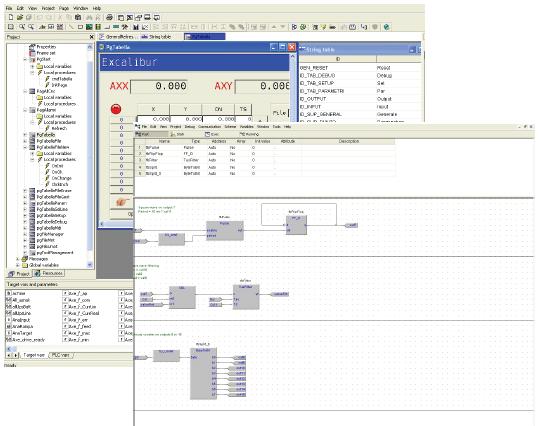

Pixsys Suite Logiclab Overview

Movicon Graphic Software Overview

Development enviroment for TD430-570-700 HMi/PLC`s. Powerful programme software for both screen display & logic aspects with extensive test and de-bug tools. 5 programming languages available includes; ladder, IL, function block, ST, SFC according to IEC 61131-3

ETD1644 PLC module for TD Range HMI & Panel PC

16 programmable digital I/O, outputs PNP- 3 Encoder Push-Pull res. 32 bit max 80 KHz -

4 analogue inputs (res. 16bit) selectable: TC type K, J, S, R (automatic compensation of the cold junction 0-50 degC, accuracy @ 25degC +/-0,2% F.S. or +/-1 digit), Thermoresistances PT100, PT500, PT1000, Ni100, PTC1K, NTC10K (B 3435K), linear inputs (0) 4-20mA (40000 points), 0-10V (54000 points), 0-40mV (16000 points), potentiometers F.S. 6/150Kohm (50000 points) 4 programmable analogue outputs 4-20 mA/ 0-10 VoltPixsys Modbus & Canbus expansion modules

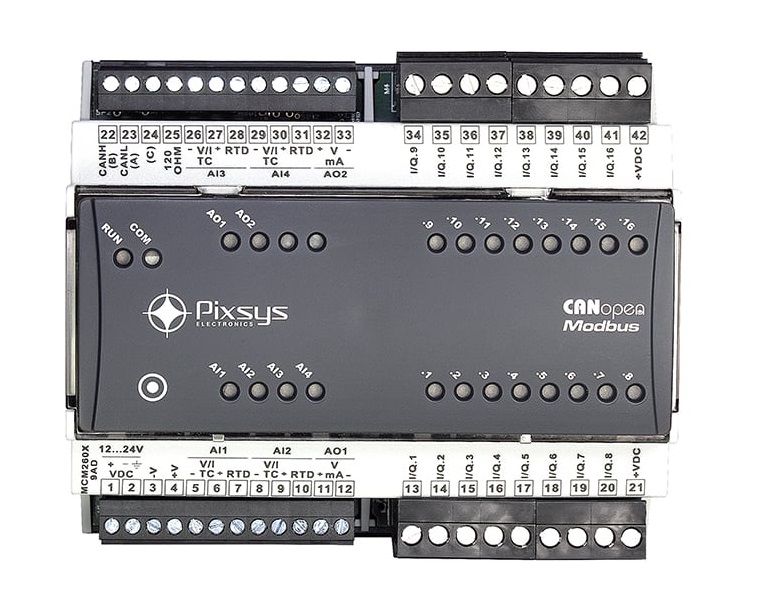

MCM260X-1AD 16 Digital outputs 700mA MCM260X-2AD 16 Digital outputs PNP MCM260X-3AD 8 Digital outputs 700mA + 8 Digital inputs PNP MCM260X-4AD 8 Relay outputs 5A + 8 Digital inputs PNP MCM260X-5AD 4 Analogue inputs V,mA,TC,RTD,mV & 2 Analogue outputs V/mA

Din rail mount expansion modules for Pixsys and third party devices, all modules utilize both Can Open and Modbus RTU protocol, user selectable input types and communication settings. 12-24VAC/DC supply.

Analogue I/O & High Speed digital I/O Combination

MCM260X-9AD 4 Analogue inputs V,mA,TC,RTD,mV & 2 Analogue outputs V/mA, 16 Digital I/O

MCM260X-9AD universal analogue signal and 16 digital I/O DIN rail expansion with Modbus RTU slave protocol. 4 universal 16-bit analogue inputs, 2 analogue outputs programmable for 0-10V or 4-20mA. 8 high speed digital PNP inputs and 8 digital PNP outputs max 700mA resistive load.

Pixsys STR 571 RTU Modbus Master | Slave Display

STR571 Modbus RTU Display

STR571 is a compact operator panel for any Modbus RTU third party master or slave devices. It has two RS485 ports (one master, one slave). It can perform read or writes/edit functions for up to 8 registers in any Modbus word format. Alternativley enumerative function allows up to four messages to be assigned to register numbers for status message display. Two relays can be assigned to variables as alarm outputs & 3 logic inputs can be used for multiple functions including alarm reset

Discontuinued

PL500 PLC with Modbus / Canbus ..Discontuinued

PL700 / PLE500 PLC

Technical Information for PL500 PLC

PL500 / PLE500 Pixsys modular PLC series consists of CPU PL500 control unit and connectivity node, based on ARM CORTEX A8 -1 GHz microprocessor, featuring extensive range of serial ports and protocols: RS485, RS232 (Modbus RTU), Ethernet (Modbus TCP/IP), CanOpen. Various combinations of digital & analogue I/O are available with PLE500 modules including direct Thermocouple & RTD inputs. Communication between CPU and I/O modules is via a real-time DIN-rail internal Bus . Development environment LogicLab is compliant with IEC 61131 standards, it is the same for PL series PLC as for Pixsys HMI and Panel PC, thus optimal sinergy among different series and connectivity with third-party hardware thanks to wide list of drivers included.

PL250-11AD ..Discontuinued

Compact PLC for applications requiring flexibity with up to 28 digital I/O. All resources are available in a single device. CPU, power supply unit, digital I/O (with relay outputs) , analogue I/O including mA, volts, RTD, thermocouple sensors K,J,R,S,T,N not requiring external signal conditioners. Serial communication via RS485 multi-point and Modbus RTU, counters, timers, PID control algorithms, motion control, mathematical and logical functions

PL260 PLC with Canbus ..Discontuinued

PL260-11AD

Compact PLC for applications requiring flexibity with 16 digital Inputs, 16 static digital outputs with LED. All resources are available in a single device. CPU, power supply unit, digital I/O (with relay outputs) , analogue I/O including direct mA, mV, RTD & thermocouple sensors. RS485 CANbus & Modbus RTU serial communications, counters, timers, PID control algorithms, motion control, mathematical and logical functions

Pixsys TD240 HMI with inbuilt PLC 3.5 ..Discontuinued"

Compact colour 3.5" 320 x 240 pixel touchscreen Human Machine Interface ( HMI ) with optional analogue and digital I/O, 4 universal inputs; mA or V (16bit) temperature sensors PT100, NI100 TC K,J,S,T,R,E, 16 digital I/O 4 analogue outputs (12bit), ModBUS serial comms master and slave, counters, timers, PID control algorithms, motion control, mathematical and logical functions

COPYRIGHT 2010 - 2024 UCONTROL PTY LTD AUSTRALIA ABN 18 150 270 161